Everything You Need To Know About Hex Bolts

May 13, 2025

Uses and Functions of Hex Bolts

How To Remove A Stripped Hex Bolt

● Coatings

● Strength

Hex bolts are the common go-to fastener for many purposes. But that is an umbrella term that could mean a lot of things. And for your next build to succeed, every part has to be reliable and durable, down to the teeny-tiny pieces. A hex bolt can make or break your project, so read on and find out which ones suit your purpose best.

What is a hex bolt?

A hex bolt is simply a bolt with six sides on its head. You’ve probably seen a handful of them tossed in a toolbox. It’s the go-to for demanding purposes like building, machinery, and automobile production. They’re a reliable option for a heavy-duty fastener ready to withstand intense pressure without breaking.

Its six-sided head gives your wrench something to latch onto, making turning easier and safer. Some hex bolts are threaded all the way, while others are just threaded near the end. You’ll also find some with an extra layer of coating to prevent corrosion. Whether you’re starting a new project or fixing something old, a hex bolt gives you a strong, reliable hold.

Uses and Functions of Hex Bolts

Hex bolts are typically used for tough jobs. And with their robust build, they work well in places where strength matters, like in bridges, towering buildings, and engines. In machines and cars, they help hold big, moving parts together without coming loose. The shape of its head also allows easy tightening, even if the space is tight or awkward.

You’ll also spot hex bolts in your everyday life, like in your furniture, shelves, or home repairs. When used with nuts and washers, they keep everything steady and secure. Since they’re easy to remove and use again, they’re perfect for projects that need checking or fixing over time. If you need something strong and reliable, hex bolts are a solid choice.

How To Remove A Stripped Hex Bolt

Got a tripped hex bolt? Spray some oil to loosen it up a bit and let it sit for a few minutes. Then grab a set of locking pliers or a bolt extractor and apply a steady, even pressure. Don’t rush since going too fast can make the damage worse.

If it’s still not moving, try cutting a straight groove into the bolt head using a rotary tool. You can then fit a flathead screwdriver into the groove and twist it out slowly. If that doesn’t work, drill into the bolt and use a reverse-thread extractor to pull it free. If all else fails, you may need to drill the whole thing out and repair the hole.

Types of Hex Bolts

To save you some time, here are hex bolts at a glance:

|

TYPES OF HEX BOLTS |

|||||||||||

|

Material: |

Alloy Steel |

Stainless Steel |

Brass |

Aluminum |

|||||||

|

Coating: |

Galvanized |

Zinc (Clear and Yellow) |

Chrome/Nickel/Bronze |

||||||||

|

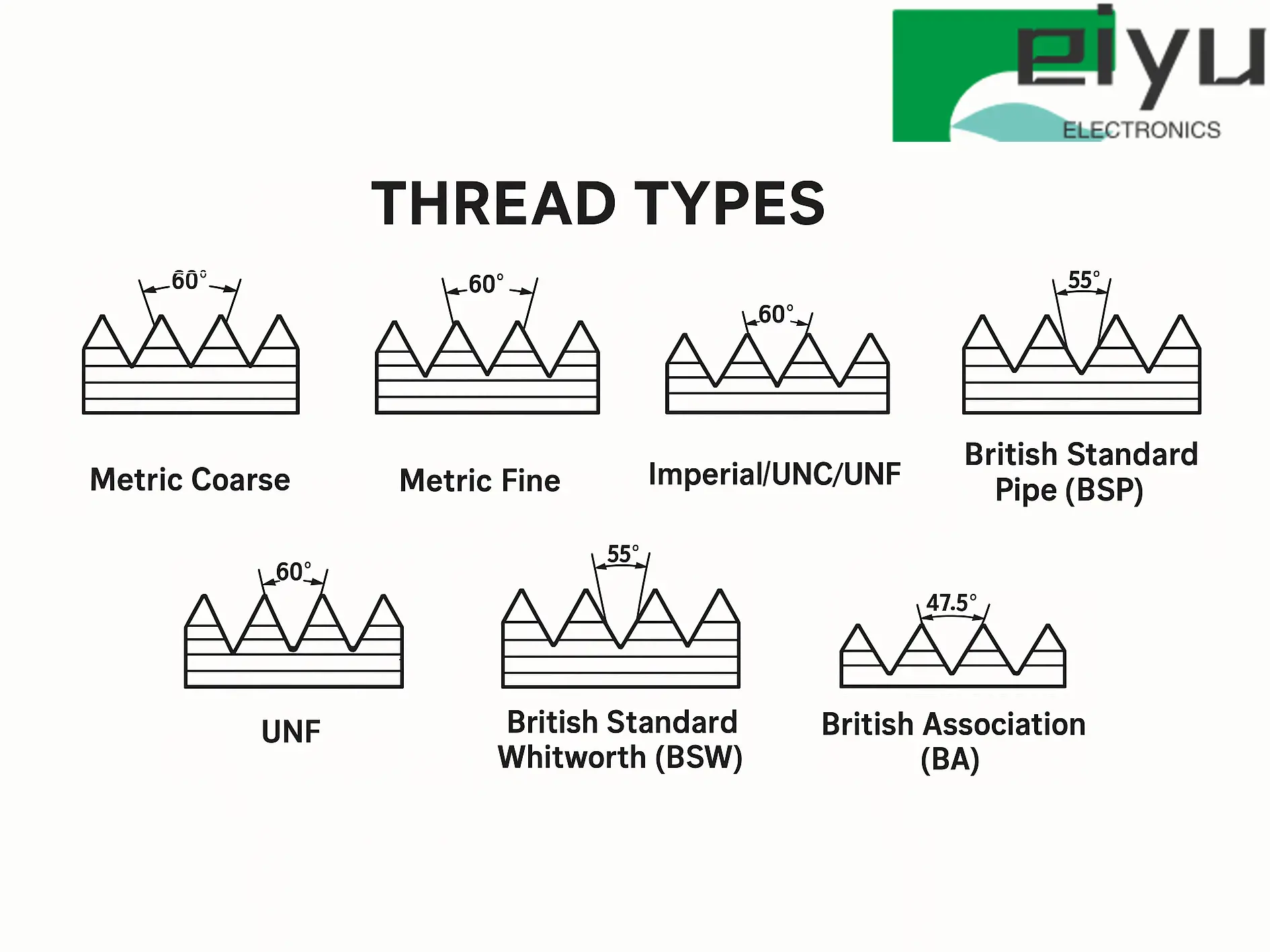

Thread Type: |

Metric Coarse |

Metric Fine |

Imperial/ UNC/UNF |

British Standard Pipe |

Unified National Fine |

British Standard Whitworth |

British Association |

||||

Materials

Alloy Steel

A.k.a. Grade 8, alloy steel is the best choice when high tensile strength can make or break the situation. It’s made for heavy equipment, cars, and building projects where the fastener is expected to withstand high levels of pressure.

Stainless Steel

The most common material used for general purposes and outdoor use. Stainless steel offers excellent corrosion resistance, making it a great choice for purposes where moisture is a factor.

Brass

Just like stainless steel, brass hex bolts are equipped with reliable corrosion resistance and tensile strength. However, they are typically pricier, so most people still opt for SS.

Aluminum

Another budget-friendly material, aluminum, provides a reasonable amount of tensile strength that can face general use and corrosion. However, it's weaker than SS or alloy steel, so it might not be suited for heavy-use purposes.

Coatings

Galvanized

Alternatively called Hot-Dip or HD, galvanized coating is your best bet if corrosion resistance is your top priority. With better protection than stainless steel, you can count that it stays tough for rugged outdoor use. It’s the usual fastener for anything built close to the coast to avoid damage from extreme salt exposure.

Zinc

The affordable alternative to galvanized hex bolts, zinc coating is the ideal fastener if you’re in a humid setting. Usually, it’s available as a clear coating but, if it undergoes electroplating, then it will turn yellow. For purposes that involve liquid, a zinc coated hex bolt got you covered.

Chrome/Nickel/Bronze

The cheapest coating with the least corrosion resistance, these kinds of coatings are mainly used for aesthetics. Think of accessories, picture frames, figurines and other decors where strength isn’t much of a factor.

Threading

Partially Threaded Hex Bolts

Partially threaded hex bolts have heads connected by a bit of grip length to the screw thread. This smooth grip length in the shaft of the bolt offers reliable resistance and is designed to tackle heavy use.

Fully Threaded Hex Bolts

This type of hex bolt has screw threads in its entire body. It offers its best performance when used in a threaded hole where it fits like a glove. This configuration allows maximum pressure distribution, offering better fastening than its partially threaded counterparts.

Thread Type

Metric Coarse: Large threads for hex bolts that are needed for general use at home. It offers tough strength for fastening where vibration isn’t a big factor.

Metric Fine: The ideal option for precision and better vibration resistance, metric fine has smaller threads than metric coarse.

Imperial/UNC/UNF: USA’s standard choice for engineering purposes. Unified National Coarse and Unified National Fine are specialized threads for specific uses, like in car manufacturing and machine assembly.

British Standard Pipe (BSP): As its name suggests, BSP is the UK's go-to hex bolt for plumbing and other pipe jobs. It’s equipped with 55-degree angled threads that best serve its purpose.

UNF: Unified National Fine is the hex bolt used for general purposes and was first introduced during the Second World War. This allows easy repairs and building between allied forces such as the US, UK and Canada. It features a 60-degree fine thread and is usually found in automotives and machinery.

BSW: The British Standard Whitworth has a 55-degree coarse threading that originated during the industrial revolution. Even though it’s been decades since it was first introduced, this hex bolt is still used to this day.

BA: The 47.5-degree threading of the British Association hex bolt is the common fastener for small purposes. It’s not as popular as before, but some musical instrument manufacturers still choose this hex bolt for their products. Some optics and metering equipment also feature BA due to their small size and tensile strength.

Hex Bolt Sizes

Determining hex bolt sizes depends on a few factors: thread type, length, and thread pitch (no. of threads/inch). Keep in mind that any label with “M” only means the outer diameter of the hex head. So if you see one with “M5”, it means the outer diameter of the hex head is 5 millimeters.

Remember, it’s tough to pinpoint which exact hex bolt size will suit every project. But here’s a quick glance at the general hex bolt sizes:

|

DIN 931/Partially Threaded Hex Bolt Sizes |

||||||

|

Thread Size |

Thread Diameter |

Threaded Shank Length (mm) (up to 125mm) |

Threaded Shank Length (mm) (125-200mm) |

Threaded Shank Length (mm) (200+mm) |

Head Width |

Thread Width |

|

M4 |

0.7 |

14 |

n/a |

n/a |

2.8 |

7 |

|

M5 |

0.8 |

16 |

22 |

n/a |

3.5 |

8 |

|

M6 |

1 |

18 |

24 |

n/a |

4 |

10 |

|

M8 |

1.25 |

22 |

28 |

n/a |

5.3 |

13 |

|

M10 |

1.5 |

26 |

32 |

45 |

6.4 |

17 |

|

M12 |

1.75 |

30 |

36 |

49 |

7.5 |

19 |

|

M14 |

2 |

34 |

40 |

53 |

8.8 |

22 |

|

M16 |

2 |

38 |

44 |

57 |

10 |

24 |

|

M20 |

2.5 |

46 |

52 |

65 |

12.5 |

30 |

|

DIN 933/Fully Threaded Hex Bolt Sizes |

||||

|

Thread Size |

Thread Pitch |

Thread Width (mm) |

Head Width (mm) |

Radius Under Head (mm) |

|

M12 |

1.75 |

17.5-18 |

7.5 |

0.6 |

|

M16 |

2 |

23-24 |

10 |

0.6 |

|

M20 |

2.5 |

29-30 |

12.5 |

0.8 |

Strength

Working with hex bolts marked “A2” on the head? Then they use 304 stainless steel as the main material. Another common label is “A4” for 316 stainless steel hex bolts. Now, if you see A2-70, the “70” indicates the bolt’s tensile strength. Just multiply it by 10 and you get 700 megapascals.

5.8, 8.8, 10.9, or 12.9 are also typical labels. These numbers tell you how strong the bolt is and its build. You can multiply the first number by 100 to get the minimum tensile strength in megapascals. Then multiply the second number by 10 to find the yield strength percentage.

This helps you know how much force the bolt can take before it begins to stretch.

Here’s a chart to help you easily identify hex bolts and their relative strengths:

|

METRIC |

||||

|

Marking/Class |

Material |

Proof Load |

Min. Yield Strength (MPa) |

Min. Tensile Strength (MPa) |

|

8.8 |

Medium Carbon Steel |

580-600 |

640 |

800 |

|

10.9 |

Alloy Steel |

830 |

660 |

830 |

|

12.9 |

Alloy Steel |

970 |

940 |

1040 |

|

A2/A4 |

Steel Alloy + Chrome/Nickel |

Varies |

210-450 |

1220 |

|

US |

||||

|

307A |

Low Carbon Steel |

N/a |

N/a |

60,000 |

|

Grade 2 No Mark |

Low/Medium Carbon Steel |

33,000-55,000 |

36,000-57,000 |

74,000 |

|

Grade 5 3 Lines |

Medium Carbon Steel |

74,000-85,000 |

81,000-92,000 |

105,000-120,000 |

|

Grade 8 6 Lines |

Medium Carbon Alloy Steel |

120,000 |

130,000 |

150,000 |

|

A325 |

Carbon/Alloy Steel |

85,000 |

92,000 |

120,000 |

|

18.8/316 |

Steel Alloy + Chrome/Nickel |

N/a |

20,000-65,000 |

65,000-100,000 |

|

615 |

Copper/Tin |

N/a |

40,000-55,000 |

55,000-70,000 |

|

2024 |

Aluminum + Copper/Magnesium/Manganese |

N/a |

36,000 |

55,5000 |

Remember that tensile strength refers to the maximum load the hex bolt can handle before breaking by pulling. Yield strength, on the other hand, is the maximum load it can bear in a permanent position. Proof load is the tensile load the bolt must carry without showing any damage.

Just keep in mind: 1MPa = 1N/mm2 = 145 pounds/inch2

Hex bolts are everywhere. It can be challenging to find the type that perfectly fits your needs. But once you’re equipped with this knowledge, it all becomes easier. No more wondering if the hex bolt you used can handle the load. You can build and repair anything efficiently.

You can now easily pinpoint the type, size, thread type, thread size, and strength of hex bolts for any purpose.

FAQs

What’s the difference between an Allen hex bolt and a hex bolt?

Hex bolts have a six-sided head and need a wrench for tightening/loosening. Allen hex bolt (socket head cap screw) has a six-sided socket in the head where an Allen tool would fit.

What is the toughest hex bolt?

A325 in US Standard is the toughest bolt with a minimum of 120,000 MPa tensile strength. It’s used in structural connections that require a reliable fastener like heavy engines and infrastructures.

;